It’s common to read about the number of stitches per square meter in a given turf. But, do we know what they are? How are they made up?

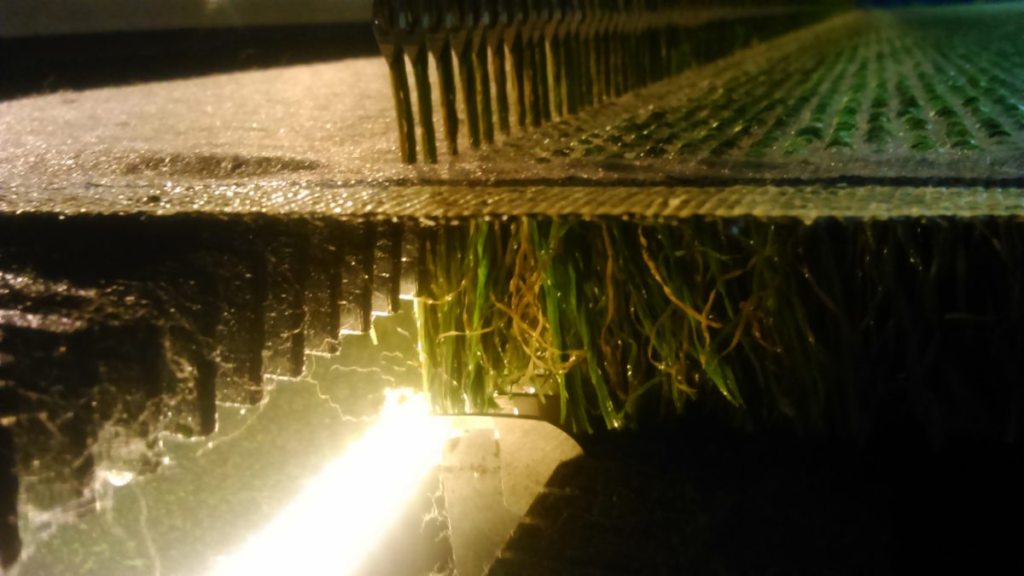

In the manufacturing process for artificial turf, the thread, both monofilament and textured, are stitched to the backing or primary support. This process is carried out by knitting needles, which insert the thread, and this is collected needle by needle by individual hooks set to obtain the desired height for each type of turf.

At the same time, each hook corresponds to a blade that cuts the loop formed to release the 8 strands of thread (or those that correspond to the product) and obtain its final appearance and height.

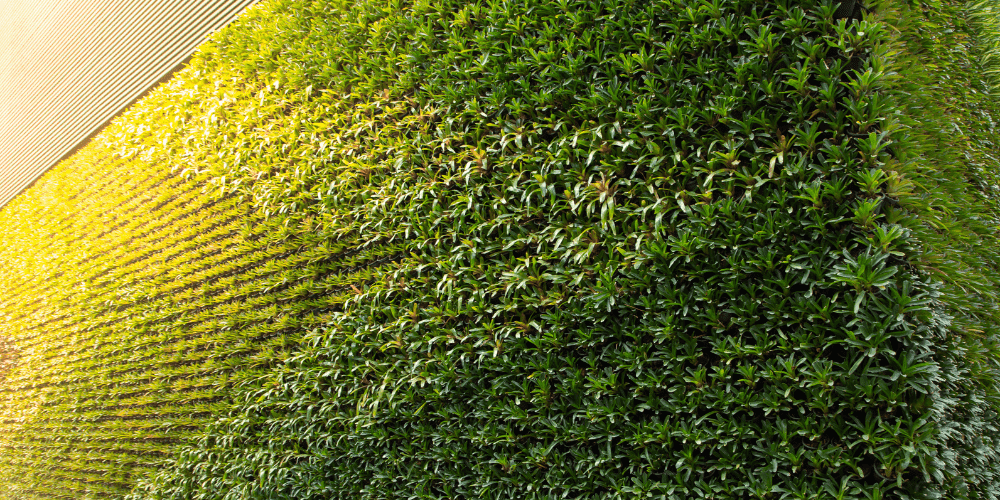

In this way, the thread is stitched to the backing, from the front we can see the artificial turf already with its final appearance and from the back we can see the stitches of thread sewn to the backing (each of the loops that are seen). Now the grass is ready to go to the final phase of finishing and rolling.

Depending on the distance between needles (gauge) and the amount of stitches per linear meter, we obtain the number of stitches per square meter.

As a general rule, the higher the stitches, the denser the turf is and therefore has better quality. However, we can have a grass with many stitches, but with little decitex, so it gets a good appearance, but the durability will be less than that of a grass with fewer stitches and more decitex.

As always, we advise you to consider more than one variable when comparing different types of turf.

If you have doubts about what stitches are, feel free to write us. As well if you are already thinking about installing artificial turf but you need advice to make a good decision.