Before you choose; ask and compare.

The decision about which artificial turf to choose for our garden, is one of those decisions that if taken knowing more characteristics and qualities of the product, will certainly help us to make it the right one and the most suitable for our needs.

We are going to list and explain a series of basic concepts to make your choice easier.

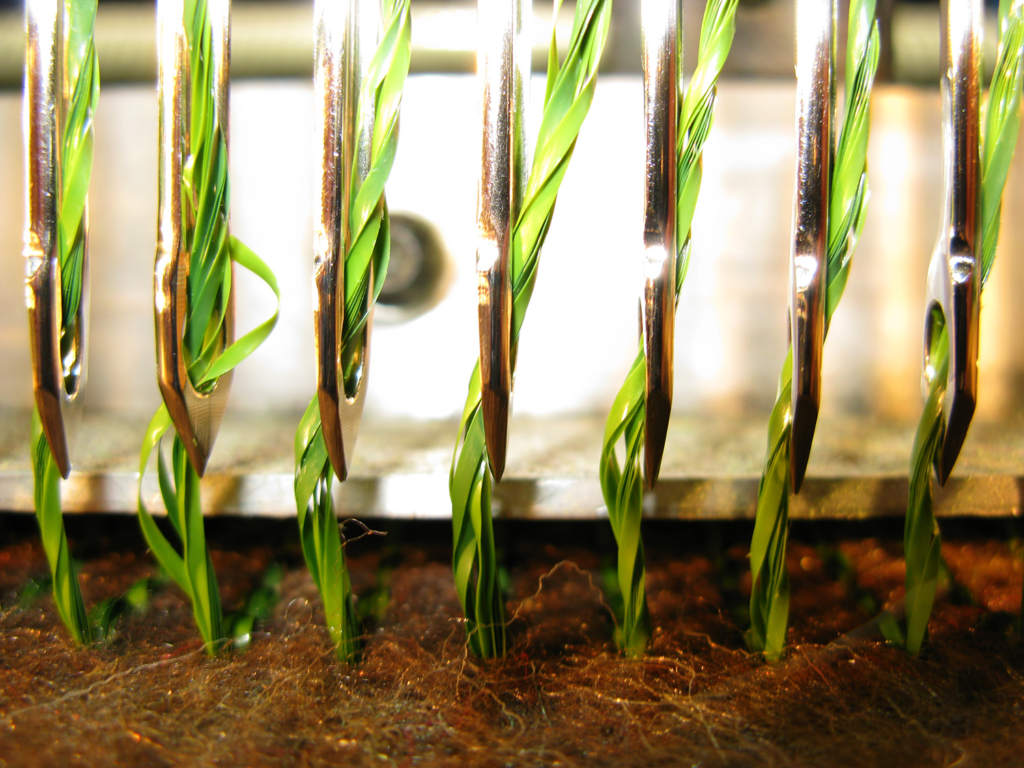

Let’s start with the type of yarn. There are two types of yarn used in the manufacture of turf:

- Straight yarnalso known as monofilament, it is the yarn that will give us the visual aspect of the lawn as it is the one that is more visible. It is important that this yarn complies with quality standards so that the good appearance lasts over time. We must take into account factors such as UV protection to prevent premature discoloration, its internal shape which will mark the resistance to the tread and the softness to the touch, the width of the fiber measured in microns which will provide durability and a thicker appearance, the decitex which will mark the weight of the yarn used, which is very important for durability, and the raw material from which it is made.The most commonly used material for this yarn is polyethylene, from the quality of the polyethylene to the additives used in its extrusion, which will allow us to define aspects such as the brightness of the fiber, heat accumulation and final color. The most commonly used material for this yarn is polyethylene, with which we obtain a very good resistance-smoothness ratio.

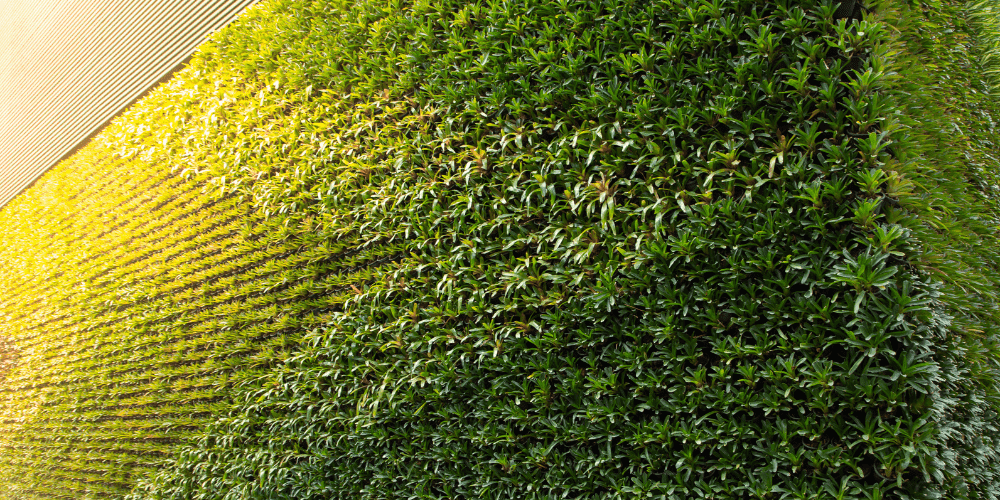

- Curly or textured yarnThis yarn will be below the straight yarn as its main function is to serve as a support for it. Although it is a less visible yarn, it will also influence the appearance and although we may think that it is a secondary yarn, its quality and characteristics are equally important to achieve a quality lawn. It must be taken into account that it meets the same quality standards as the straight yarn, such as decitex, fiber width measured in microns, UV treatment and its composition. In this case,softness and resistance are important, being polyethylene the one with which we achieve a better result; although if what we are looking for is resistance and durability, polyamide is undoubtedly the material to choose.

We have discussed many characteristics to be taken into account in the two types of yarn used. For this reason, weWe are going to explain a little more these characteristics that influence them a littlemore:

Unit of measurement of the yarn that indicates the weight in grams of 10,000 meters of yarn. The decitex value will indicate whether the yarn is thicker or thinner. The higher the decitex value, the thicker the fiber.

There are many types of internal structures, such as central rib, C-shape, V-shape, W-shape… In Albergrass we look for the perfect balance between structure, decitex and microns to offer maximum strength and durability.

UV protection:

The quality of the additives used to provide the yarn with optimum UV protection is very important, as this will determine the stability of the color over time, and therefore the appearance and durability of the yarn.

Heavy Metals:

It is of vital importance for health make sure that the turf to be purchased does not contain heavy metals. At Albergrass podeus that the raw materials we use and the raw eare free from the presence of heavy metals.

Primary backing:

It is the support on which the fibers are woven. Specially designed for this purpose to ensure maximum durability and stability. Depending on the type of turf, sports or residential for example, the type of support will vary to always guarantee optimum performance.

Defines the number of yarn loops per square meter, a clear indication to check the amount of fiber contained in the turf along with the height.

Refers to the height of the straight thread from the base or primary support and is expressed in mm. The height is also a key factor when deciding on one type of grass or another depending on the use we are going to give it or simply for appearance.

Secondary Baking or Latex:

The latex es which joins the fiber, straight yarn and crimped yarn with the primary support. Of utmost importance since the anchorage of the fibers and therefore the durability of the turf depends on it. Specially formulated for this purpose and to maintain flexibility and avoid cracks, thus facilitating installation.

Drainage:

Perforations made in the primary backing once the latex has been applied and cured to facilitate drainage and prevent puddling.

Knowing more about the grass, its composition, manufacturing process, quality controls, origin and warranty is very important when deciding on one or another and we hope this article has been helpful to you when making your decision. making a decision.

But if you need more information or advice, do not hesitate to contact us.